| Model | CCT/Color | CRI | Input Voltage | Rated Current | Rated Power | Lumen (LM) | Efficiency (LM/m) | Size | Max. Length |

| ECN-Ø23 (2835-336D-6mm) | 2700K | >90 | 24V | 0.6 | 14.4 | 1271 | 86 | Ø23 | 5000mm |

| 3000K | 1271 | 86 | |||||||

| 4000K | 1271 | 86 | |||||||

| 6000K | 1295 | 90 | |||||||

| ECN-Ø23-R/G/B (2835-120D-24V-6mm) | R:620-630nm | / | / | / | |||||

| G520-530nm | |||||||||

| B:457-460nm | |||||||||

| ECN-Ø23-SWW (2216-280D-6mm) | 3000K | >90 | 718 | 93 | |||||

| 5700K | >90 | 783 | 100 | ||||||

| 3000K-5700K | >90 | 1486 | 97 |

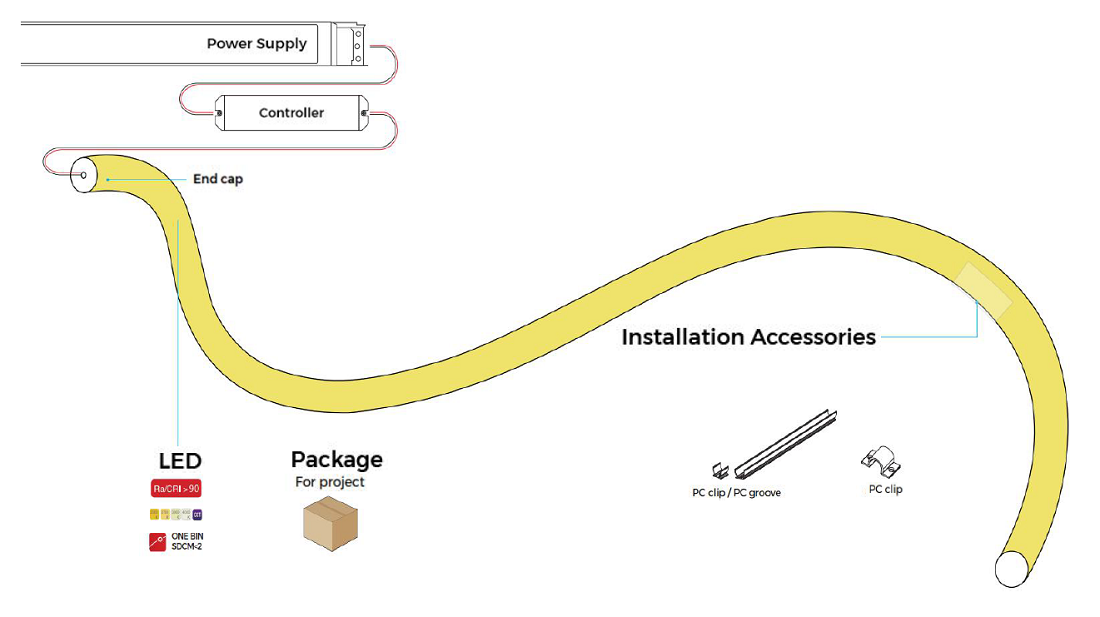

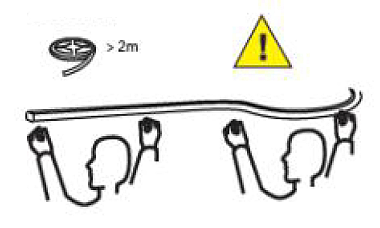

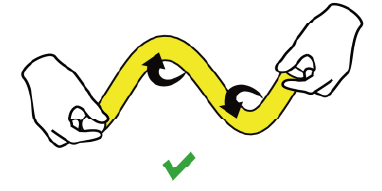

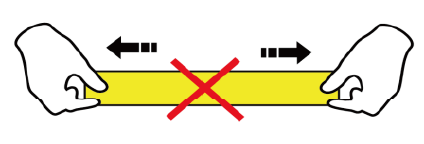

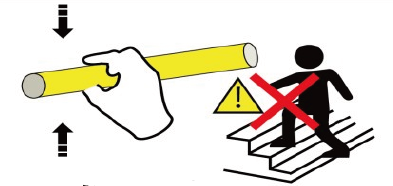

Features and advantages of Silicone Neon LED Strip A.High substitutability Silicone neon strip lights featuring high substitutability, all neon strip can achieve various lighting effects such as white light, RGB and digital toning, it can replace the neon tube, guardrail tube, rainbow tube and so on for signage lighting/architectural lighting/landscape lighting. B.High thermal conductivity High thermal conductivity, the thermal conductivity of silicone is 0.27W/MK, better than the “0.14W/MK” of PVC material, and the light strip features longer effective heat dissipation life. C.Resistance to UV Neon light strips featuring resistance to UV, the extrusion silicone can be used outdoor environment for long-term exposure to direct sunlight, no yellowing and aging over 5 years. D.Flame-retardant and environmental Neon strip is environmental and non-toxic, with high ignition point, non-flammable in needle-flame burning, and without irritating toxic gases volatilizing (not like PVC), which is more secure. E.Resistance to corrosive gases Neon led strip lights are resistance to corrosive gases, include chlorine, sulfur dioxide, hydrogen sulfide, nitrogen dioxide and so on, the silicone neon strip with long life span can be used for severe environment F.Dust proof Avoid dust into the neon strip, and featuring reliable sealing, up to IP6X, beautiful appearance, wide range of applications and long-life span. G.Uniform Lighting Uniform Lighting, dot-free, direct-view surface, used for highly reflective material, featuring a glossy environment free from dazzling. H.High light transmittance Neon light strips with high light transmittance up to 90%, can meet the requirements of high lumens output, and it’s not only used for decoration but also lighting. I.Good flexibility Reliable structure with good flexibility, adopting solid silicone, customizing internal structure and external form by mould. Neon led strip can be bent and twisted, suitable for various shapes, with resistance to tear and draw, it is not easy to damage and deform with good flexibility. J.Outstanding weather resistance Outstanding weather resistance, storing in the environment between -50℃ and +150℃ , neon strip can maintain the normal-soft state, without embrittlement, deformation, softening and aging. And using in the environment between -20℃ and +45℃ , neon led strip lights can operate normally resisting extremely cold and high heat. K.Resistance to corrosion Neon light strips featuring resistance to corrosion, the silicone can resist corrosion of normal salt, alkali and acid, can be used for special environments such as beach, yacht, chemical industry, petroleum, mine and laboratory. L.Good protective performance Good protective performance,the main body of neon led strip and standard outlet end cap can be used in the environment up to IP67 standard, and can pass the laboratory test standards of IP68

Features and advantages of Silicone Neon LED Strip A.High substitutability Silicone neon strip lights featuring high substitutability, all neon strip can achieve various lighting effects such as white light, RGB and digital toning, it can replace the neon tube, guardrail tube, rainbow tube and so on for signage lighting/architectural lighting/landscape lighting. B.High thermal conductivity High thermal conductivity, the thermal conductivity of silicone is 0.27W/MK, better than the “0.14W/MK” of PVC material, and the light strip features longer effective heat dissipation life. C.Resistance to UV Neon light strips featuring resistance to UV, the extrusion silicone can be used outdoor environment for long-term exposure to direct sunlight, no yellowing and aging over 5 years. D.Flame-retardant and environmental Neon strip is environmental and non-toxic, with high ignition point, non-flammable in needle-flame burning, and without irritating toxic gases volatilizing (not like PVC), which is more secure. E.Resistance to corrosive gases Neon led strip lights are resistance to corrosive gases, include chlorine, sulfur dioxide, hydrogen sulfide, nitrogen dioxide and so on, the silicone neon strip with long life span can be used for severe environment F.Dust proof Avoid dust into the neon strip, and featuring reliable sealing, up to IP6X, beautiful appearance, wide range of applications and long-life span. G.Uniform Lighting Uniform Lighting, dot-free, direct-view surface, used for highly reflective material, featuring a glossy environment free from dazzling. H.High light transmittance Neon light strips with high light transmittance up to 90%, can meet the requirements of high lumens output, and it’s not only used for decoration but also lighting. I.Good flexibility Reliable structure with good flexibility, adopting solid silicone, customizing internal structure and external form by mould. Neon led strip can be bent and twisted, suitable for various shapes, with resistance to tear and draw, it is not easy to damage and deform with good flexibility. J.Outstanding weather resistance Outstanding weather resistance, storing in the environment between -50℃ and +150℃ , neon strip can maintain the normal-soft state, without embrittlement, deformation, softening and aging. And using in the environment between -20℃ and +45℃ , neon led strip lights can operate normally resisting extremely cold and high heat. K.Resistance to corrosion Neon light strips featuring resistance to corrosion, the silicone can resist corrosion of normal salt, alkali and acid, can be used for special environments such as beach, yacht, chemical industry, petroleum, mine and laboratory. L.Good protective performance Good protective performance,the main body of neon led strip and standard outlet end cap can be used in the environment up to IP67 standard, and can pass the laboratory test standards of IP68

Top bend series neon LED strip, bending direction: vertical. This series adopt environmental silicone material, up to IP67 protection level. High light transmission, can be used for sign lighting, indoor and outdoor decorative lighting and architecture contour lighting molding.

Top bend series neon LED strip, bending direction: vertical. This series adopt environmental silicone material, up to IP67 protection level. High light transmission, can be used for sign lighting, indoor and outdoor decorative lighting and architecture contour lighting molding.ECN-Ø23

*Note: The above date is based on the color temperature of 4000K monochrome.1. Interior design, such as decoration of home, hotel, KTV, bar, disco, club etc. 2. Architectural design, such as decorative lighting of buildings, edge lighting decoration etc. 3. Advertisement project, such as outdoor illuminated signs, billboard decoration etc. 4. Display design, such as decoration of drinks cabinet, shoe cabinet, jewelry counter etc. 5. Underwater lighting engineering, such as decoration of fish tank, aquarium, fountain etc. 6. Car decoration, such as motorcar chassis, inside and outside of car, high brake decoration etc. 7. City beautification, landscape design, holiday decoration and so on.