Full scene led strip which can help you optimize your products list, reduce the mix color mistake cost, lower the purchasing communication cost, saving the warehouse stock management cost, and better the marketing and sales person product training cost etc. Our LED strip provides four series of tape light, including “PRO Series”, “STD Series”, “Toning Series” and “Neon Series”. Customers can select the most suitable led tape in terms of the applications, requirements of functions, projects, and budgets. Adheres to independent R&D and sustaining innovation, and our products passed the ISO9001 QMS & ISO14001 EMS certification. All products have passed the testing of the third-party authoritative laboratories and have attained the quality certification from a variety of countries and regions: CE, REACH, ROHS, UL, TUV, LM-80 and so on.

Full scene led strip which can help you optimize your products list, reduce the mix color mistake cost, lower the purchasing communication cost, saving the warehouse stock management cost, and better the marketing and sales person product training cost etc. Our LED strip provides four series of tape light, including “PRO Series”, “STD Series”, “Toning Series” and “Neon Series”. Customers can select the most suitable led tape in terms of the applications, requirements of functions, projects, and budgets. Adheres to independent R&D and sustaining innovation, and our products passed the ISO9001 QMS & ISO14001 EMS certification. All products have passed the testing of the third-party authoritative laboratories and have attained the quality certification from a variety of countries and regions: CE, REACH, ROHS, UL, TUV, LM-80 and so on.| Model | LEDs/m | DC(V) | Preview | Cutting Unit (LEDs/mm) | Power (W/m) | LM/m | CRI | FPC Width (mm) | Warranty (year) |

| ECDS-C120-24V-12mm | 120 | 24 |  | 6/50 | 9.6 | 1020 | >80,>95 | 12 | 3 |

| Model | Size | Input Current | Typ. Power | Max. Power | Beam Angle | Copper Foil |

| ECDS-C120-24V-12mm | 20000*8*1.5mm | 0.363A/m & 7.1A/5m | 8.7W/m | 9.6W/m | 120° | 3oz |

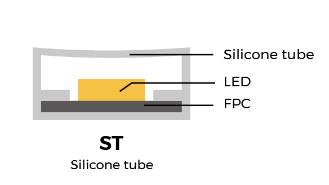

| ECDS-C120-24V-12mm IP Process |  |

*All the information displayed are for your reference only and subject to our final confirmation.※ Please drive the led strip with required isolated power, and the ripple of the constant voltage source should be less than 5%. ※ Please do not bend the strip into an arc with a diameter less than 60mm to ensure the longevity and reliability. ※ Do not fold it in case any damage of LED beads. ※ Do not pull the power wire hard to ensure the longevity. Any Crash may damage the LED light is prohibited. ※ Please make sure the wire is connected to the anode and cathode correctly. The power output should be consistent with the voltage of the strip to avoid damage. ※ LED lights should be stored in dry, sealed environment. Please only unpack it before usage. Ambient temperature: -25℃~40℃.Storage temperature: 0℃~60℃.Please use the strips without waterproof within indoor environment with humidity less than 70%. ※ Please be careful during operation. Do not touch the AC power supply in case of electric shock. ※ Please leave at least 20% power for the power supply during using to ensure there is enough power supply to drive the product. ※ Do not use any acid or alkaline adhesives to fix the product (e.g.: glass cement).

*All the information displayed are for your reference only and subject to our final confirmation.※ Please drive the led strip with required isolated power, and the ripple of the constant voltage source should be less than 5%. ※ Please do not bend the strip into an arc with a diameter less than 60mm to ensure the longevity and reliability. ※ Do not fold it in case any damage of LED beads. ※ Do not pull the power wire hard to ensure the longevity. Any Crash may damage the LED light is prohibited. ※ Please make sure the wire is connected to the anode and cathode correctly. The power output should be consistent with the voltage of the strip to avoid damage. ※ LED lights should be stored in dry, sealed environment. Please only unpack it before usage. Ambient temperature: -25℃~40℃.Storage temperature: 0℃~60℃.Please use the strips without waterproof within indoor environment with humidity less than 70%. ※ Please be careful during operation. Do not touch the AC power supply in case of electric shock. ※ Please leave at least 20% power for the power supply during using to ensure there is enough power supply to drive the product. ※ Do not use any acid or alkaline adhesives to fix the product (e.g.: glass cement).